The Impact of Robotics on Manufacturing

The manufacturing industry has always been at the forefront of innovation, constantly seeking ways to improve efficiency, productivity, and quality. In recent years, the integration of robotics into manufacturing processes has revolutionized the industry, paving the way for significant advancements in automation and production. As robotics technology continues to evolve at a rapid pace, it is poised to bring about a fundamental shift in how products are made. Let’s delve into how robotics is set to change the face of manufacturing.

Enhanced Efficiency and Precision

One of the most significant benefits of incorporating robotics into manufacturing is the enhanced efficiency and precision it offers. Robots are capable of performing repetitive tasks with unparalleled speed and accuracy, reducing the margin of error in production processes. This level of precision not only ensures consistent quality but also minimizes waste and rework, ultimately leading to cost savings for manufacturers. By automating tasks that were previously done manually, robots can streamline operations and increase overall productivity.

Flexibility and Adaptability

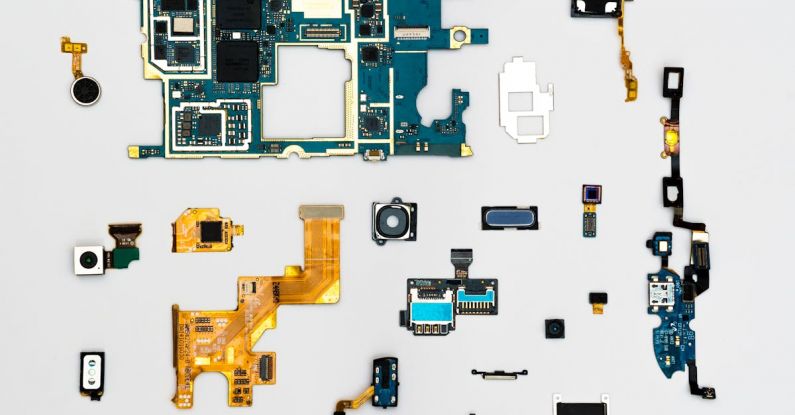

Another key advantage of robotics in manufacturing is the flexibility and adaptability they provide. Modern robots are designed to be highly versatile, capable of performing a wide range of tasks across different production lines. With the use of advanced sensors and programming, robots can easily be reconfigured or reprogrammed to handle new products or processes, making them ideal for agile manufacturing environments. This flexibility allows manufacturers to quickly respond to changing market demands and maintain a competitive edge in the industry.

Safety and Ergonomics

Robots are also instrumental in improving workplace safety and ergonomics in manufacturing facilities. By taking on hazardous or physically demanding tasks, robots help reduce the risk of workplace injuries and create a safer working environment for employees. Additionally, robots can operate in confined spaces or harsh conditions where human workers may be at risk, further enhancing safety protocols. With the ability to handle heavy loads and perform repetitive motions without fatigue, robots not only protect workers from harm but also contribute to overall employee well-being.

Cost-Effectiveness and Return on Investment

While the initial investment in robotics technology may seem substantial, the long-term benefits far outweigh the costs. Implementing robots in manufacturing processes can lead to significant cost savings through increased efficiency, reduced labor costs, and minimized waste. By streamlining operations and optimizing production workflows, manufacturers can achieve a higher return on investment and improve their bottom line. Additionally, the scalability of robotics technology allows for future expansion and growth without the need for extensive capital expenditures, making it a cost-effective solution for manufacturers of all sizes.

Quality Control and Consistency

Maintaining consistent quality standards is crucial in manufacturing to ensure customer satisfaction and brand reputation. Robotics play a vital role in quality control by performing precise measurements, inspections, and testing throughout the production process. By detecting defects or deviations early on, robots help prevent costly errors and ensure that only high-quality products reach the market. The reliability and repeatability of robots contribute to consistent output and adherence to strict quality standards, setting a new benchmark for excellence in manufacturing.

The Future of Manufacturing with Robotics

As robotics technology continues to advance, the future of manufacturing holds even more exciting possibilities. From collaborative robots that work alongside human operators to autonomous systems that can make real-time decisions, the integration of robotics is set to transform the way products are designed, produced, and delivered. With the potential to revolutionize supply chains, enhance customization capabilities, and drive innovation, robotics is poised to shape the future of manufacturing in ways we have yet to imagine. Embracing this technological revolution will be key for manufacturers looking to stay ahead in an increasingly competitive and dynamic industry landscape.

In conclusion, the integration of robotics into manufacturing processes is not just a trend but a transformative shift that will redefine the industry in the years to come. By leveraging the power of robotics to enhance efficiency, flexibility, safety, and quality, manufacturers can unlock new opportunities for growth and innovation. With the relentless march of technological progress, the face of manufacturing is undergoing a profound change, and embracing robotics is the key to staying ahead in the evolving landscape of the industry.